Cutting Through Confusion: Your Guide to Buying the Right Sliding Miter Saw

So What’s The best sliding compound miter saw. So, you’re thinking about adding a sliding miter saw to your workshop? Smart move! It’s a powerhouse tool for making precise angled cuts (miters) and beveled cuts in wood, trim, and even some other materials. But with different sizes, slide mechanisms, and features, choosing the right one can feel overwhelming. Don’t worry – this guide cuts through the jargon to help you make an informed decision based on your needs.

First Things First: What Makes a “Sliding” Miter Saw Special?

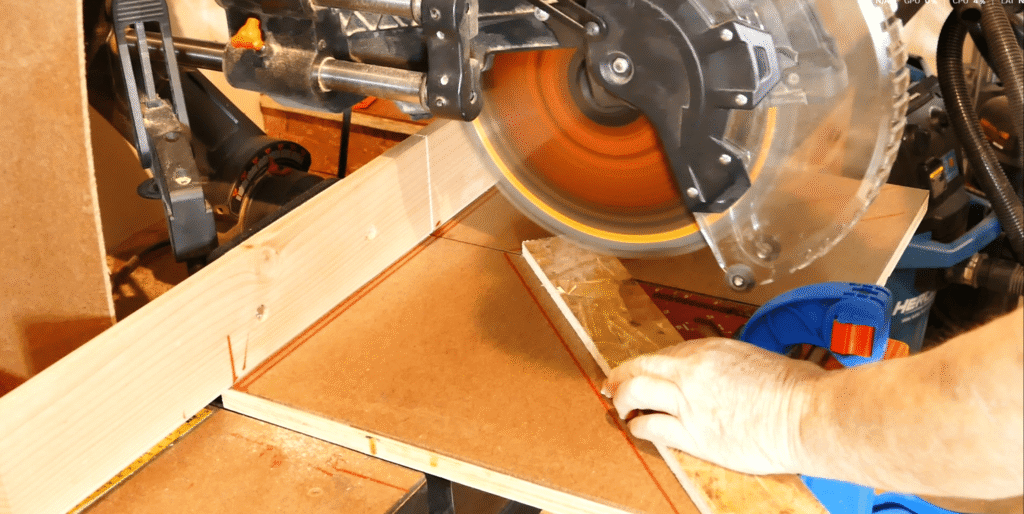

Unlike a standard miter saw (which pivots only left and right for angles), a sliding miter saw has rails or arms that allow the blade and motor assembly to slide forward and backward towards and away from you. This sliding action dramatically increases the width (cross-cut capacity) of material you can cut in a single pass. Think wide baseboards, crown molding laid flat, thick stock, or decking boards.

Key Factors to Consider (Without the Hype):

- Cutting Capacity: Check the SPECS!

- Cross-Cut Capacity (Width): The maximum width of board the saw can cut at 90 degrees. This is where the slide shines. Crucially: This capacity decreases as you increase the miter angle or bevel angle. Always check the manufacturer’s specs for capacities at common angles (like 45 degrees), not just the maximum 90-degree width.

Subscribe to my Youtube Channel and get more woodworking tip and tricks each month. SUBSCRIBE HERE

Vertical Cutting Height (Depth):

- The maximum height/thickness of a board the saw can cut vertically at 90 degrees. Primarily determined by blade size (12-inch cuts deeper than 10-inch).

- Blade Size (Diameter): This directly impacts cutting depth and capacity.

- 10-inch: The most common and versatile. Offers a good balance between cutting capacity (usually around 12″ crosscut on a slide) and portability/workspace needs. Great for trim, DIY projects, framing, and smaller stock.

- 12-inch: Provides greater cutting depth (thicker material) and often wider cross-cut capacity (up to 14″ or more). Ideal for larger dimensional lumber, deck building, thicker crown molding, and heavier-duty tasks. Downsides: Heavier, bulkier, requires more space behind it (see “Slide Mechanism” below), and blades are more expensive.

- Which for you? If you primarily work with standard dimensional lumber (2x4s, 2x6s), trim, and typical DIY projects, a 10-inch is often sufficient and more manageable. If you regularly tackle thicker stock (like 4x4s or 6x6s) or very wide boards, the extra capacity of a 12-inch shines.

- What to do? Honestly assess the largest pieces of material you realistically plan to cut. Don’t just look at the headline “max cut” number – dig into the spec sheet for capacities at angles you’ll use.

Slide Mechanism: How the Saw Glides

Rails (Rear Rails): The classic design. Rails extend horizontally behind the saw. Pros: Generally, offer the longest possible slide and maximum cross-cut capacity. Cons: Requires significant space behind the saw (often 12-18+ inches) against a wall. Can sometimes interfere with tall workpieces clamped vertically.

Compact/Over-the-Top Slide (Arms): Newer designs where the slide mechanism is above or around the back of the saw head. Pros: Requires much less space behind the saw (often only 3-6 inches), making it ideal for tight workshops or against walls. Cons: May have slightly less maximum cross-cut capacity than comparable rail slides (though often still ample for DIY), and the mechanism can sometimes feel slightly less rigid than heavy rails.

Which for you? Measure your workspace! How much space do you have between the back of your saw’s planned location and the wall? If space is tight, a compact slide is almost essential. If you have ample space and need every inch of cutting width, rear rails might be preferable.

Dust Collection:

Let’s be real: Miter saws create a lot of dust. Most have a dust port you can connect to a shop vacuum. Effectiveness varies greatly. Look for designs that try to capture dust at the source (around the blade guard). Good dust collection isn’t just about cleanliness; it’s about visibility and health. A saw with a well-designed dust shroud connected to a vac is infinitely better than just the port alone.

Laser Guides & Shadow Lines:

These project a line or shadow indicating where the blade will cut. Can be helpful, especially for beginners. However, they are not essential. Many experienced woodworkers rely solely on the blade and the saw’s physical fences/indentations. Accuracy can vary between models. Consider this a “nice-to-have” feature, not a deal-breaker. Traditional blade-to-mark alignment is always reliable.

Weight & Portability:

Sliding miter saws are heavy tools. 10-inch compact slides are generally the lightest and easiest to move. 12-inch saws with full rails are beasts. If you need to transport the saw frequently (e.g., job sites), weight and the quality of the built-in carry handle matter. For a stationary workshop setup, weight is less critical than stability.

Single Bevel:

The saw head tilts only in one direction (usually left) to make bevel cuts. To make a matching bevel cut in the opposite direction, you need to flip your workpiece around.

Dual/Compound Bevel:

A dual-bevel saw tilts both left and right, and that simple feature saves a ton of time. When you’re cutting crown molding, picture frames, or any tricky angle, you don’t have to wrestle with flipping long or awkward boards. Plus, a compound cut just means the saw can tilt for a bevel while also turning for a miter at the same time, which makes those complex cuts a lot easier.

Which one should you pick?

If you plan on doing regular trim work—especially crown molding—or you’re building furniture or anything that needs frequent compound angles, then a dual-bevel saw is the way to go. However, if you’re mostly doing basic framing or you only hit bevel cuts once in a while, a single-bevel saw still gets the job done, just with a little less convenience.

Putting it All Together: Your Buying Checklist

- Assess Your Projects: What will you cut most often? (Trim? Framing lumber? Thick hardwood? Wide decking?)

- Measure Your Space: How much depth do you have behind the saw? (This dictates Rail vs. Compact Slide).

- Determine Needed Capacity: What’s the widest and tallest piece you need to cut? Check specs at relevant angles.

- Consider Bevel Needs: Will you do complex trim or angles? If yes, prioritize Dual Bevel.

- Set a Realistic Budget: Factor in potential future needs. Buying slightly more capacity/features than you need now can be wise if your skills/projects grow.

- Read Reviews (Focus on Functionality): Look for comments on dust collection, build quality/stability, slide smoothness, and accuracy (checking/adjusting the saw is normal, but it should hold settings well). Ignore pure sales pitches.

Remember: HOW TO BUY SLIDING MITER SAW. The “best” sliding miter saw is the one that best fits your specific projects, workspace constraints, and budget. There’s no single winner for everyone. By understanding these key features and how they relate to your actual woodworking needs, you’ll be well-equipped to walk into the store (or browse online) with confidence and find the perfect tool to make your cuts precise and efficient. Happy (and safe) woodworking!

Subscribe to my Youtube Channel and get more woodworking tip and tricks each month. SUBSCRIBE HERE