Here’s the truth most beginners don’t realize: the factory throat plate that comes with your table saw is holding you back. In fact, those wide gaps around the blade aren’t doing you any favors. That’s because that’s exactly where offcuts fall, small pieces get launched, and the edges of your boards get torn up. Fortunately, a zero-clearance plate could solve these issues effectively.

If you’ve been woodworking for a while, you’ve probably cursed a few times after seeing a nice piece of wood chewed up at the edge of a cut. Well, that little splintered mess—called tear-out—is thHere’s the truth most beginners don’t realize: the factory throat plate on your table saw is actively holding you back. Why? Those wide gaps around the blade create real problems. Specifically, offcuts plunge through them, the blade launches small pieces, and rough edges tear up your boards. Fortunately, a zero-clearance plate solves every one of these issues.

If you’ve ever winced at seeing a beautiful piece of wood chewed up during a cut, you know the frustration of tear-out. Ultimately, this splintering is what separates an amateur-looking project from a flawless, “store-bought” finish. However, a zero-clearance insert provides crucial support right up to the blade, which dramatically minimizes this splintering.

Therefore, the simple upgrade is this: swap out that stock plate for a zero-clearance version. Immediately, your table saw will perform as if it just received a professional tune-up, giving you cleaner cuts and greater control from the very first use.e kind of thing that separates a “good enough” project from a “that looks store-bought” project. With a zero-clearance solution, however, such splintering can be minimized.

So, if you swap it out for a zero-clearance throat plate, your table saw will suddenly perform like it’s had a professional tune-up.

What Is a Zero-Clearance Throat Plate?

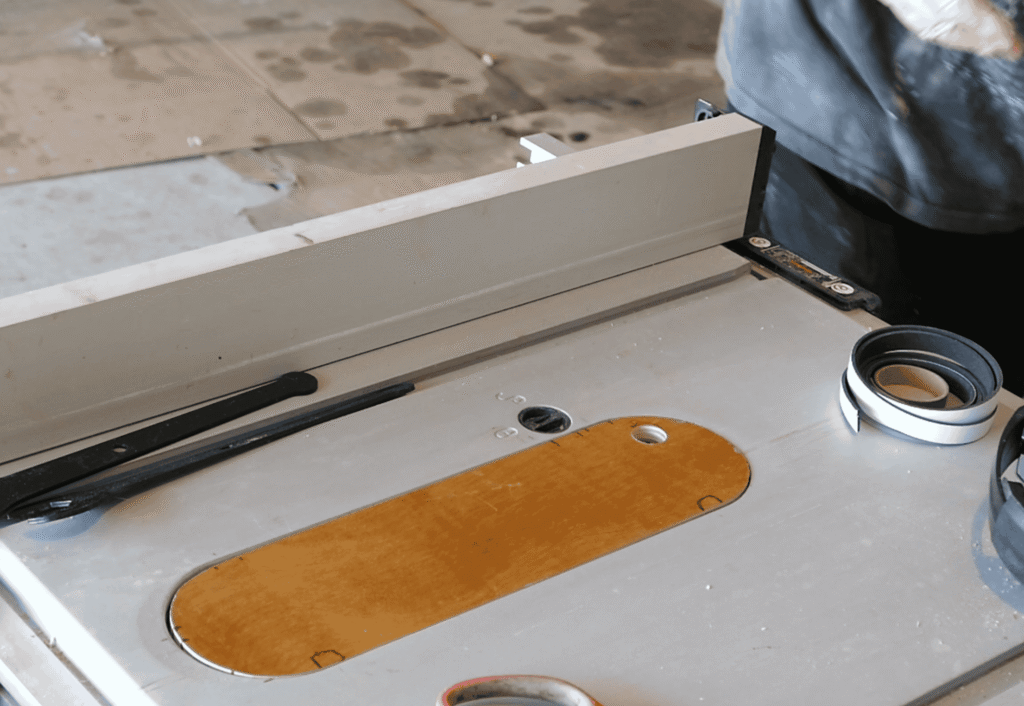

A zero-clearance throat plate is a custom insert that fits snugly into your saw’s table — but here’s the key difference: the slot around the blade is exactly the width of your saw blade. No gaps. No wiggle room.

It’s called “zero-clearance” because the blade slices into it the first time you use it, creating a perfect fit for your exact blade thickness. That tight clearance supports your workpiece on both sides of the cut. It provides you with super clean edges and far less splintering.

It’s like the difference between cutting wood on a wobbly card table versus a rock-solid workbench. Everything just feels more precise, making a zero clearance plate essential.

The Benefits of a Zero-Clearance Throat Plate

1. Cleaner, smoother cuts

This is the top reason most woodworkers make the switch. The zero-clearance insert supports the wood fibers right next to the blade, keeping them from lifting or tearing. You’ll notice an instant improvement in the quality of your cuts — especially with plywood or fine hardwoods.

2. Less tear-out and edge damage

If you’ve ever cut birch plywood and watched the surface explode along the cut line, you know the frustration. With a zero-clearance plate, the edges stay sharp and clean. There’s no more sanding or filler to hide rough spots.

3. Safer, more controlled cutting

Those factory throat plates have big openings where small pieces can fall in, kick back, or even wedge against the spinning blade. Using zero clearance in your setup keeps your material supported. Additionally, it keeps your fingers safer. It’s not a gimmick — it’s genuine peace of mind.

4. A cleaner workspace

Less sawdust and debris fall below the table because of the tighter fit. That helps with dust control and keeps your workspace tidier. A cleaner shop is safer and more enjoyable to work in.

5. Custom inserts for every cut

You can make different inserts for different blades. One for your dado stack, another for your thin-kerf blade, and even one for bevel cuts. Once you’ve made a few, switching them out only takes seconds.

Store-Bought vs. DIY — Which Should You Choose?

You can absolutely buy pre-made zero-clearance inserts, and some fit beautifully right out of the box. But here’s a secret many garage woodworkers already know — making your own is a quick and satisfying weekend project. Crafting a zero clearance plate can be both cost-effective and rewarding.

All you need is:

- A piece of 1/2-inch plywood or MDF

- A router or jigsaw to rough out the shape

- A flush-trim bit for a perfect fit

- And, of course, your table saw to cut the slot

Once you’ve made one, you’ll be hooked. You’ll wonder how you ever worked without it.

Final Thoughts: Small Upgrade, Big Results

A zero-clearance throat plate might not look like much, but it’s one of those upgrades that transforms how your table saw feels to use. Cleaner cuts, safer operation, and less frustration — what’s not to love?

Whether you buy one or make your own, you’ll notice the difference the very first time you push a board through. It’s one of those rare woodworking upgrades that’s cheap, simple, and genuinely game-changing. A zero-clearance plate is definitely worth the investment.

So next time you’re in the shop, take a few minutes to swap that factory insert for a zero-clearance plate. Your projects — and your patience — will thank you.

📎 Related Reading

Best Table Saw for Beginner Woodworkers on a Budget

If you’re just getting started and want a reliable saw that won’t break the bank, check out my full review and recommendations here.