Ever been totally derailed by a tiny, weird part? That’s when a woodwork shop needs a 3D printer to effortlessly create those elusive components.

Picture this: You’re deep into a big project—let’s say a beautiful custom cabinet. That’s when you realise a woodwork shop needs a 3D printer. Having a 3D printer helps when you’re in the zone. And then you see it. You need a specific, tiny bracket or a one-of-a-kind jig for your router. You hop online, but of course, nobody sells exactly what you need.

Sound familiar? It’s the worst. Your momentum just hits a wall, and that’s precisely why your woodwork shop needs a 3D printer.

But what if you didn’t have to rely on some specialty store three states away? What if you could just… make that exact part yourself, right there on your workbench?

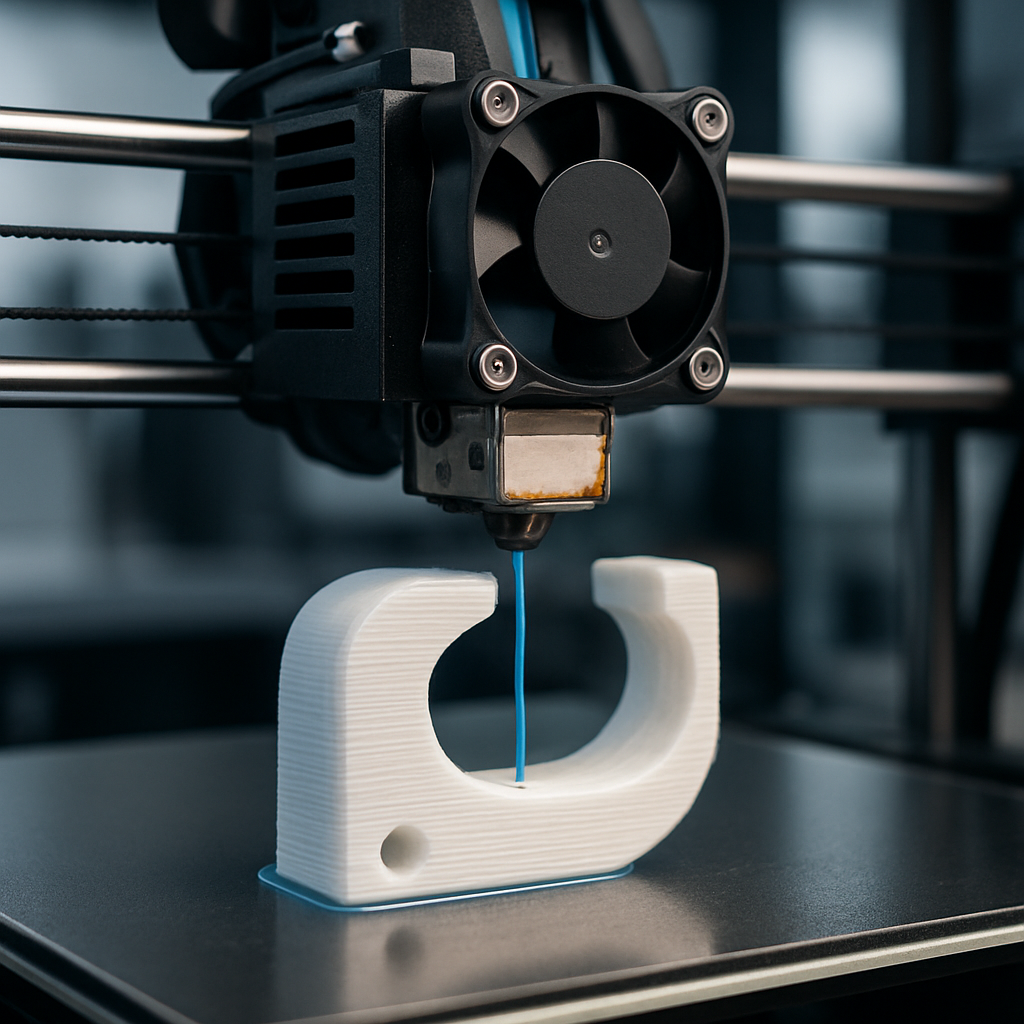

Here’s the secret: this isn’t some sci-fi dream. Honestly, grabbing a simple, affordable 3D printer is one of the smartest upgrades you can make for your shop today. It’s a total game-changer.

Your New Secret Weapon 3D printers in woodwork: Jigs & Fixtures On-Demand

Let’s get straight to the good stuff. The number one reason woodworkers fall in love with 3D printing? Custom jigs and fixtures. This is where you’ll see an instant return on your investment.

Stop measuring, start guaranteeing perfect results.

We all live by “measure twice, cut once.” But you know what’s even better? A perfect jig that makes every cut flawless.

- Custom Router Templates: Need to route a complex curve for a guitar body or a fancy inlay? Design the template in minutes and print it overnight. Boom.

- Drill Guides: Say goodbye to guesswork. Print a rock-solid guide that puts that hole in the exact right spot, every single time.

- Custom Clamping Blocks: Protect your beautiful work. Print soft-jaw blocks that match the exact contours of your piece, so you get even pressure without a single dent.

Bottom line? These custom tools save you hours, slash your waste, and let you tackle designs that used to be way too finicky. It’s clear why any woodwork shop needs a 3D printer.

Kill Hardware Headaches for Good

How many times has a project been stalled because you needed a specific spacer, a unique knob, or a dust port adapter that’s been discontinued?

This is where 3D printing shines: instant gratification.

- One-of-a-Kind Knobs and Handles: Tired of the same old brass? Print your own ergonomic, totally unique handles that make your piece stand out.

- Dust Collection Adapters: Let’s be real, this is a universal shop headache. Your tool has a 2-inch port, your hose is 2.5 inches. Instead of rigging it with duct tape, design and print a perfect, airtight adapter in 20 minutes.

- Small, Simple Parts: All those little brackets, spacers, and clips that cost pennies in plastic but dollars in frustration? You can just make them.

If you are using your printer in a dusty environment like a woodworking shop, your going to need to put it in a enclosure kit to keep it dust free

The Really Fun Part: Mixing Wood & With 3D printers in woodwork

Now, this is where it gets really cool. It’s not just about tools and hardware; it’s about the final product.

You can create stunning hybrid pieces. Imagine a gorgeous walnut box with sleek, modern 3D-printed hinges. Or a live-edge shelf supported by geometric, printed brackets.

Suddenly, you’re not just a woodworker. You’re a fabricator and a designer. You’re blending the warmth of traditional wood with the precision of modern tech, and the results are absolutely show-stopping.

The Bottom Line: It’s Time to Take Control

So, let’s be clear: adding a 3D printer to your shop isn’t just a nerdy gimmick. It’s a power move.

It gives you back your time, saves you money on overpriced hardware, and—most importantly—it completely obliterates creative limits.

Ready to stop waiting for parts and start creating them? The best part is, it’s easier and more affordable than you think. Let’s get building.

For free printing plans Just Click Here

Subscribe to my YouTube channel and get free Tips and Tricks to help you with your woodwork HERE

Key Takeaways

- A woodwork shop needs a 3D printer to create custom parts, avoiding the frustrations of searching for specific components.

- 3D printing provides instant gratification by allowing woodworkers to make unique knobs, handles, and adapters as needed.

- Custom jigs and fixtures, made with a 3D printer, enhance precision and save time on complex projects.

- Mixing wood with 3D printing enables the creation of hybrid designs, merging traditional craftsmanship with modern technology.

- Investing in a 3D printer empowers woodworkers to reclaim their time, reduce costs, and expand their creative possibilities.