How To Help Stop Your Wood From Warping When Doing Glue Ups

The Secret to doing a proper wood glue up is not Over Tightening Clamps? Knowing how to stop your wood bowing when doing glue ups is crucial for an effective and stable result. Understanding how to address the bowing of your wood during glue ups can really enhance the quality of your woodworking projects. This is How To Do A Wood Gule Up Properly

The Physics of Failure

When you over-tighten one clamp (or unevenly crank multiple clamps), you create localized stress points. As the glue cures, this uneven force pulls the wood fibers out of alignment, causing:

- Visible bowing across the joint, which needs careful handling during glue ups to prevent failure.

- Twisted panels

- Gaps that “magically” appear as stress relieves, which can affect how your wood bows during the glue up process.

Subscribe to my Youtube Channel and get more woodworking tip and tricks each month. SUBSCRIBE HERE

The Golden Rule:

“Snug, then stop.”

Your goal isn’t to crush the wood, it’s to close the joint gap evenly. When learning how to stop wood bowing during glue ups, consider what the wood needs.

Get a thin, continuous bead of squeeze out along the entire seam

(If glue floods out like a river, you’ve gone too far! And probably used too much glue)

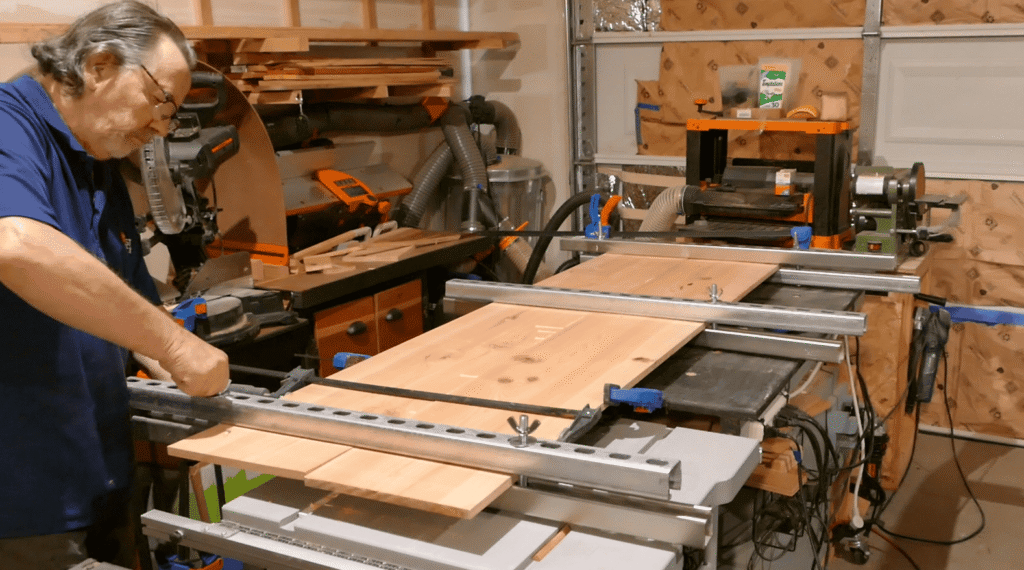

Pro Technique to Prevent Bowing:

- Don’t put rivers of glue on there is no need for that, just make sure a thin layer of glue covers the entire surface of the joint apply your clamps.

- Hand tight first: Set all clamps with light hand pressure.

- Even increments: Tighten each clamp 1/4 turn at a time, moving diagonally across the piece. This is key in your efforts to prevent bowing when doing glue ups.

- Check progress: Watch for glue beads. Stop tightening the moment a uniform line appears.

- Cauls are king: use wood clamping bars to distribute pressure and block bowing.

Why This Works:

- Wood moves under stress.

- Light, even pressure holds joints closed without overpowering the wood’s natural stability, helping you effectively stop wood from bowing.

- Let the glue cure—not the tension.

- Clamp smarter. Build flatter.

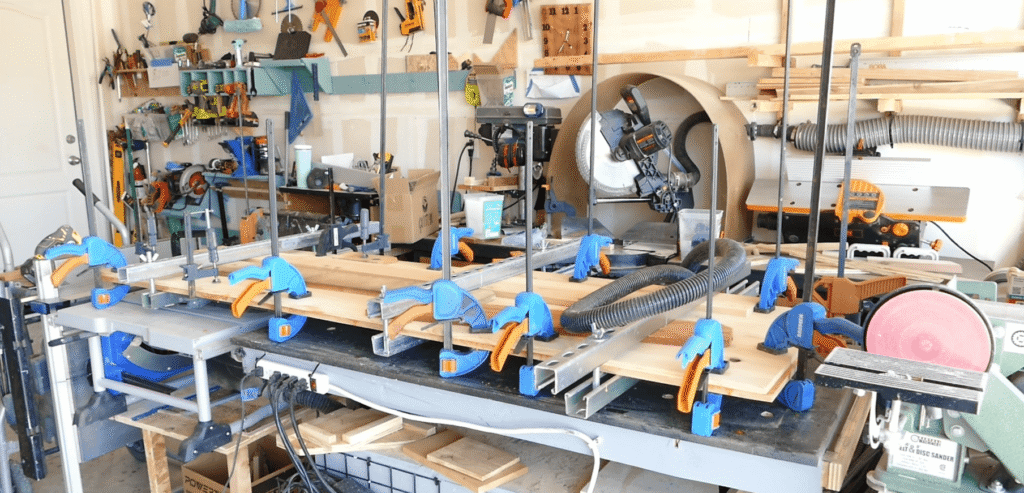

Expensive Wood Clamps? Brutal on the wallet. My DIY clamps will hold just as well; in fact, they might even hold better

Tired of paying premium prices for essential woodworking clamps? We hit our breaking point with wood clamps brutal pricing. The solution wasn’t another expensive trip to the specialty store; instead, it was cold, raw 14-gauge Super Strut from the aisles of Home Depot.

We transformed heavy-duty steel strut channel into the ultimate DIY woodworking clamps. No fancy finishes, no brand-name markup – just relentless, unyielding pressure.

The Result?

Home Depot Price: Achieves the same bone-crushing, glue-squeezing force as high-end clamps.

Fraction of the Cost: Save serious cash. Build an entire army of heavy-duty clamps without breaking the bank.

Uncompromising Strength: 14-gauge steel means zero flex, zero compromise. It holds your workpieces FLAT and TRUE for perfect glue-ups — the secret in how to stop your wood bowing.

Why Settle for Less (or Pay More)?

Stop funding the markup. Grab the 14-gauge Super Strut, your grinder, some bolts, and build clamps that hold like expensive wood clamps for a fraction of the price. Unleash the bite of raw steel on your next project. To effectively stop wood bowing during glue ups, consider using these DIY clamps.

These clamps are designed to apply even pressure across the width of the board, keeping it flat while the glue dries. They mimic the function of expensive store-bought parallel jaw clamps.? Finally, watch here as we build these DIY Wood Clamps

Subscribe to my Youtube Channel and get more woodworking tip and tricks each month. SUBSCRIBE HERE