Introduction

If you’ve ever made a cut on your miter saw and noticed rough, splintered edges on your wood, you know how frustrating it can be. The good news is there’s a simple DIY woodworking upgrade that can instantly improve your cuts, boost safety, and make your projects look more professional: the zero clearance miter saw fence. In this guide, you’ll learn exactly what it is, why it’s worth using, and how to make a zero clearance fence in just a short afternoon.

Why Use a Zero Clearance Fence?

A zero clearance miter saw fence is a custom accessory that fits snugly against your saw’s blade path. By doing this, it leaves virtually no gap between the wood and the fence, ensuring the workpiece is fully supported right up to the cutting edge.

In contrast, a standard factory fence has a wide opening to accommodate various cuts, which can lead to tear-out and reduced accuracy. Instead, a zero clearance insert is cut precisely to match your blade’s kerf, delivering ultra-clean and precise results with every pass.

For this reason, adding one is a simple upgrade that transforms your cut quality. To learn how to make and install your own, subscribe to my YouTube channel for more essential woodworking tips and tricks each month. SUBSCRIBE HERE

Best Materials for a Zero Clearance Fence

- Plywood – Affordable, stable, and easy to cut.

- MDF – Smooth surface for reduced friction and tear-out prevention.

- Hardwood strips – More durable for long-term use.

- Plastic laminate – Low-friction surface for smoother material feeding.

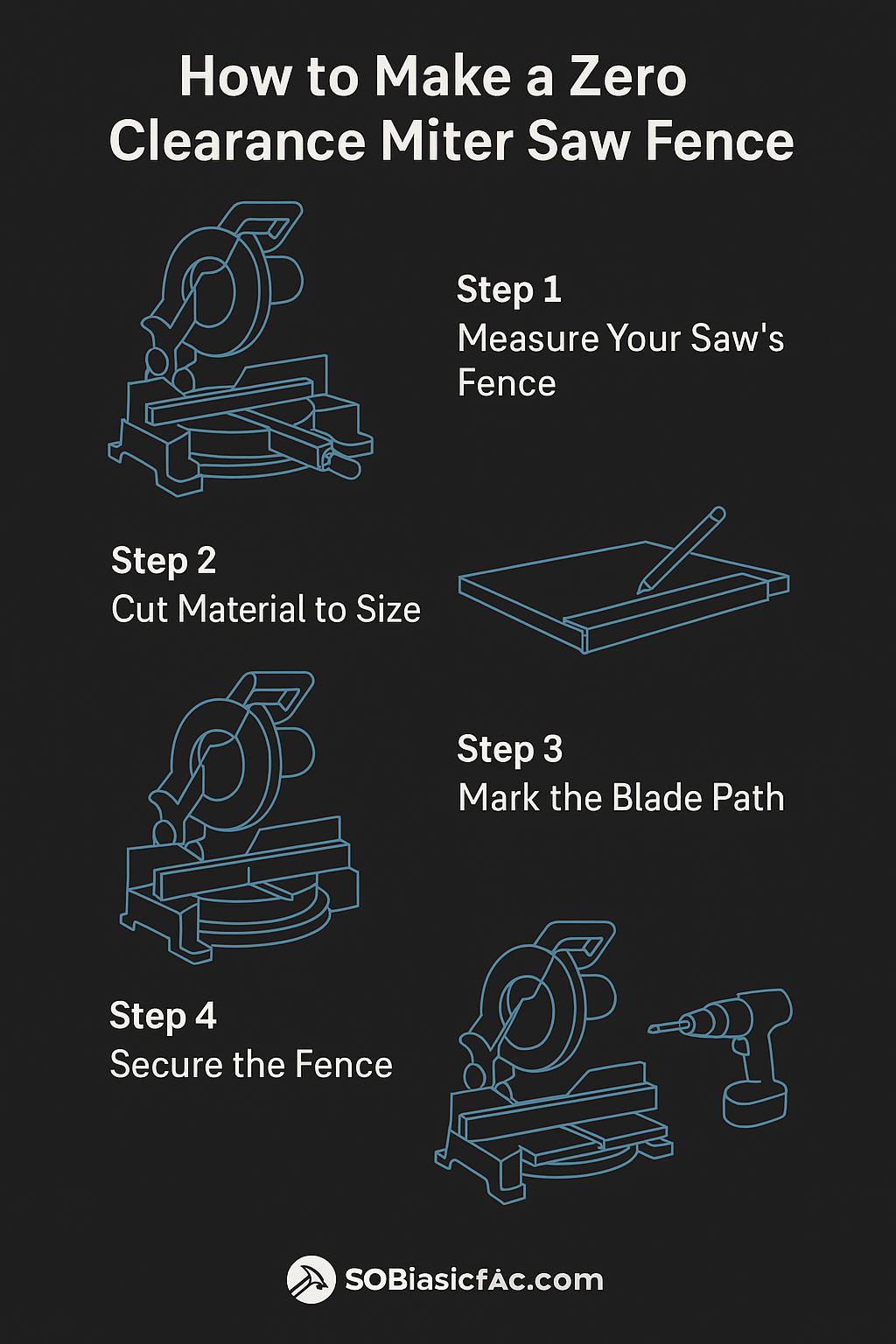

How to Make a Zero Clearance Miter Saw Fence

Step 1 – Measure Your Saw’s Fence

Measure the height and length of your miter saw’s existing fence, noting any cutouts for bevel adjustments.

Step 2 – Cut Material to Size

Cut your chosen material to match these measurements. Leave a slight overhang at the bottom if you plan to clamp it in place.

Step 3 – Mark the Blade Path

With the saw unplugged, lower the blade to mark exactly where it will pass through the fence.

Step 4 – Secure the Fence

Attach the new fence to your saw’s factory fence using screws, clamps, or quick-release brackets.

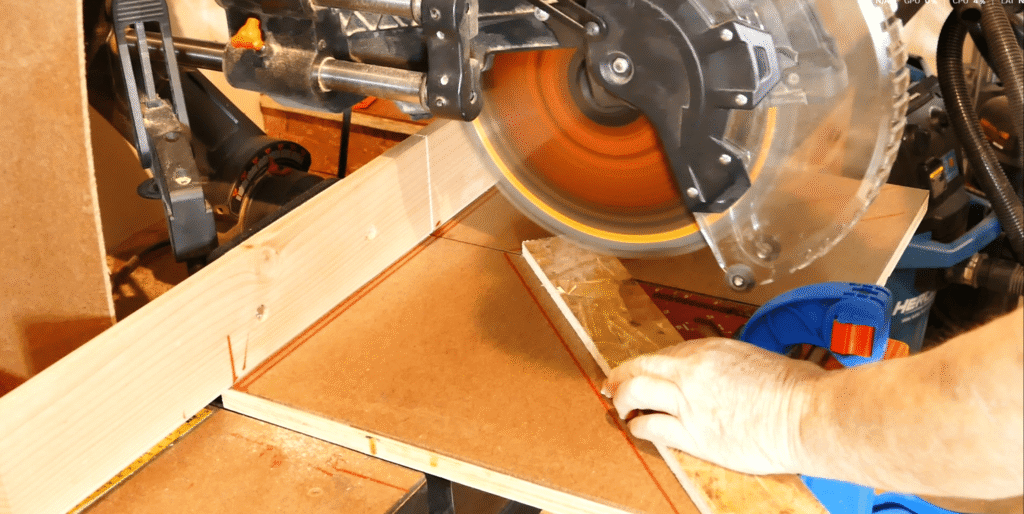

Step 5 – Make the First Cut

Power up the saw and slowly cut through the fence material to create the exact zero clearance slot.

Tips for Best Results

- Use replaceable inserts for quick changes when the fence wears out.

- Keep extra fences for different miter and bevel angles.

- Label each fence so you know which setup it matches.

- Check alignment often to maintain cutting accuracy.

Common Mistakes to Avoid

- Using material that’s too thin, which can flex and reduce accuracy.

- Forgetting to account for bevel cuts, which can cause interference.

- Blocking your saw’s built-in safety features.

Zero Clearance Miter Saw Fence – Frequently Asked Questions

Your Guide to the Zero Clearance Miter Saw Fence

1. What is the primary purpose of a zero clearance miter saw fence?

A zero clearance fence serves several key functions. Primarily, it supports your workpiece directly against the blade’s cutting path, which eliminates tear-out and splintering. Additionally, this full support enhances cut accuracy. Perhaps most importantly, it significantly improves safety by preventing small offcuts from falling into the saw’s gap and kicking back violently.

2. Can I make a zero clearance fence for any miter saw?

Yes, absolutely. This simple upgrade suits most miter saw models. The DIY process is straightforward: first, measure your saw’s existing fence; then, cut a piece of stable material like plywood to match its dimensions and attach it securely. Finally, you complete the setup by lowering the running blade through the new fence to create a perfect, zero-clearance kerf.

3. What is the best material to use for one?

Typically, woodworkers choose stable sheet goods like plywood or MDF. These materials offer an ideal balance of stability, cost, and ease of cutting. For a more durable option, consider hardwood or apply a plastic laminate surface to the fence, which provides long-lasting, smooth performance.

4. How exactly does it prevent tear-out?

The fence prevents tear-out through direct, gap-free support. Specifically, because you cut the initial kerf with your own blade, the material fully supports the wood fibers right up to the blade’s teeth. Consequently, these fibers cannot split away at the exit point, resulting in a clean, splinter-free edge on every cut.

5. Can I use it for bevel cuts?

You can, but this application requires planning. A single fixed fence often interferes with the saw head when tilted. Therefore, the best approach is to either create a separate fence for your most common bevel angle or install a system of adjustable inserts that you can swap out as needed.

6. Is a zero clearance fence worth it for beginners?

Without a doubt. This upgrade ranks among the easiest and most cost-effective improvements for any workshop. Moreover, it delivers immediate results by improving both cut quality and safety, which builds a beginner’s confidence and leads to better projects from the very start.

Subscribe to my Youtube Channel and get more woodworking tip and tricks each month. SUBSCRIBE HERE